The application area is planning, management and maintenance of biomass power plants and biomass cogeneration power stations. Our engineers mainly have a background of operating such facilities.

As for fuels, we have focussed both on solid as well as liquid biomasses.

Among solid biomasses are not only wood, but also other products like grains, grape pomace etc. Liquid biomasses are animal fats as well as plant oils and fats. Our special focus is not only on fresh biomasses, but also on the energetic utilisation of biogenic waste materials which have previously gone through one or more life cycles.

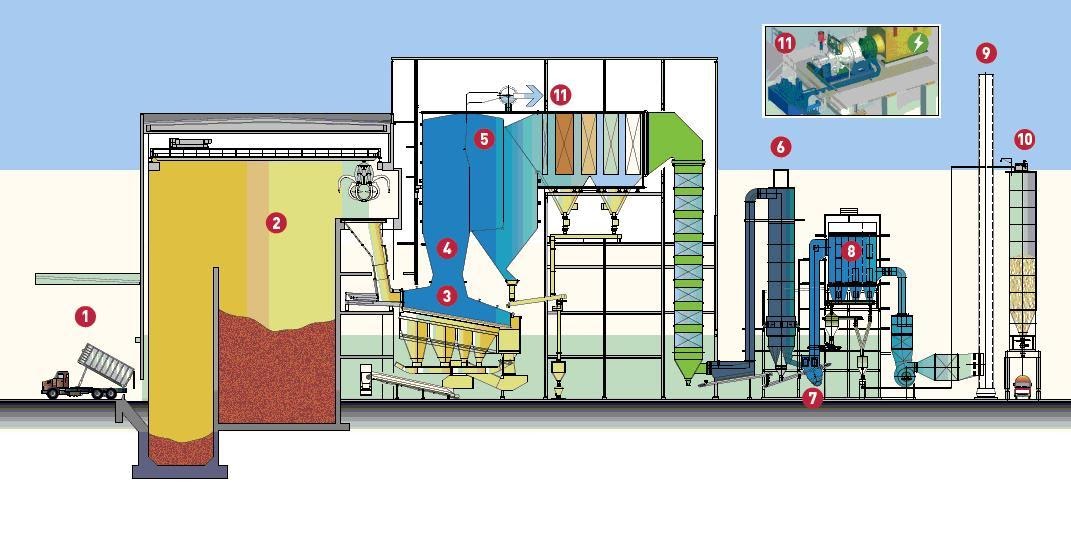

With pellet and briquette production facilities, biological fuels are converted according to specified parameters.

Among traditional fuels are:

During production, biomasses go through different processing stages like grinding, separation, drying, pressing etc. The fuels are often energetically compacted - and their specific heating value increases. This heat upgrading is the prerequisite for an effective transfer of the biomass and its use in automated combustion facilities. After the processing stage, the firing of fuels in existing large power plants is also possible. In doing so, care should be taken during the production process to ensure that the special fuel specification is complied with.